features Features of Steritainer Plus

Sterility Assurance Level (SAL) ≤ 10-6 and Low Elution

-

SterilitySteritainer Plus is a validated sterilized bag with Sterility Assurance Level [SAL] of ≤ 10-6 and can be used for storing and transporting fluids requiring a sterile environment in a container, without the need for washing and sterilization.Steritainer Plus is individually packaged with a double wrapping.

SterilitySteritainer Plus is a validated sterilized bag with Sterility Assurance Level [SAL] of ≤ 10-6 and can be used for storing and transporting fluids requiring a sterile environment in a container, without the need for washing and sterilization.Steritainer Plus is individually packaged with a double wrapping. -

Low ElutionSteritainer Plus is made from additive-free polyethylene, completely eliminating effects of dissolved materials on content fluid. Steritainer Plus can be reliably used in any process.

Low ElutionSteritainer Plus is made from additive-free polyethylene, completely eliminating effects of dissolved materials on content fluid. Steritainer Plus can be reliably used in any process. -

CleanlinessBy employing a blow-molding method in a completely closed system environment and unmanned operation processes in a cleanliness control area, Steritainer Plus completely eliminates the risk of extrinsic contamination.

CleanlinessBy employing a blow-molding method in a completely closed system environment and unmanned operation processes in a cleanliness control area, Steritainer Plus completely eliminates the risk of extrinsic contamination.

3D (three-dimensional) conformation using a blow-molding method realizing both space-saving and high-strength features

- Space-Saving Feature due to 3D Conformation

- Steritainer Plus features a space-saving installation area allowing it to be installed in locations with restricted space, such as safety cabinets. Steritainer Plus is foldable before and after use and easy to store.

- High-Strength Design Applicable to Long-Distance Transportation

- Steritainer Plus has high strength performance, which protects against breakage of the bag, even for transportation distances of 1,000 km transportation or fall from a 2 m height, so Steritainer Plus can be used for transportation between core facilities.

- Supports Freezing at -80°C

- Steritainer Plus can be used for freeze storage down to -80°C, which is applicable to biopharmaceuticals processes.

Steritainer Plus Molding Process

-

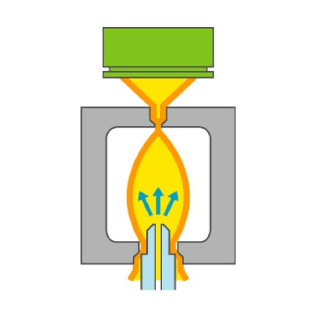

01 Parison injection

Plastic heated in the extruder is cylindrically extruded.

-

02 Mold closing

The metal mold is slowly closed, with the parison clipped by the mold parts.

-

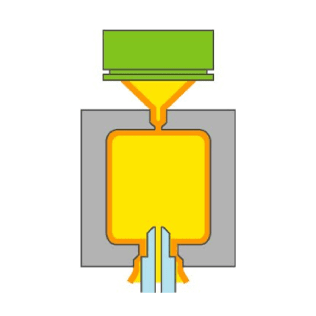

03 Blowing to cooling

The parison is inflated with blown air within the metal mold and left to stand for a while for cooling down.

-

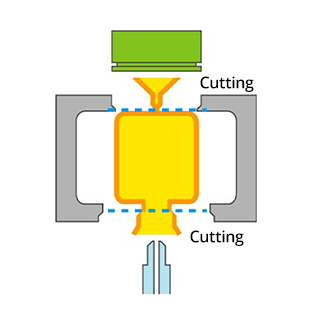

04 Taking out the product

The product is taken out from the metal mold. Unnecessary parts (burrs) are removed and recycled.

point

- The thermoforming in a closed system environment allows for complete elimination of extrinsic contamination.

- Cleanliness inside the container is ensured by filtration control of the blown air.

- All processes are fully automated, and leak tests are performed for each product on the automated line.

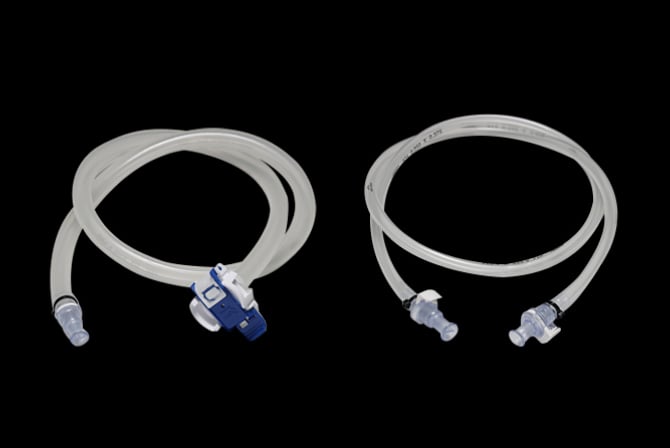

Tubing Units Enabling Various Connections in Closed Systems

- Detachable Tubing Units

- The detachable tubing unit options enables customers to freely arrange a prototype process design. In the mass production process, these tubing unit options can contribute to standardization of items.

- Ready-To-Use Standard Options

- Various standard tubing unit options are readily available. Reasonable responses can be provided in a short delivery time.

- Full Customizable Tubing Units

- In the customization of tubing, customers can freely request parts and shapes meeting their needs. Tubing unit configurations at delivery can be selected from tubing units separated from or attached to the main unit, which enables more flexible customization patterns.

Options

Tubing Options

3-Port Connector

- A connector with 3 ports for fluid injection, fluid discharge, and aeration

- Sterilized. One package contains 2 types: 1/4 inch type and 3/8 inch type.

- Used for tubing unit designs.

3-Port Connector ASSY

- A tubing unit with tubing and couplers assembled to a 3-port connector

- Sterilized. Two types are available: 1/4 inch type and 3/8 inch type.

1-Port Connector (developmental item)

- A connector specialized for injection and discharge of fluid

- Two types are available: 3/8 inch type and 1/2 inch type.

- Can be used for storage of culture medium and collection of culture solution.

Extension Tubing Unit (developmental item)

- A tubing unit with a length of 1 m used for connections to various devices

- Various specifications specialized to each device connection are available

- Can be used for tube sealers and welders.

Options for Storage and Transportation

Outer Container for Storage

- A plastic outer container which can be stacked for storage of fluid-filled Steritainer Plus

- Steritainer Plus housed in the container is for in-house storage, relocation, and transportation between core facilities.

- Two types are available: 10 L and 20 L sizes.

Vertical Flip Rack (available for both 10 L and 20 L)

- A space-saving rack used for fluid injection into and discharge from Steritainer Plus

- Residual fluid can be completely discharged by flipping the container upside down with just a single operation.

- One rack can be used for both 10 L and 20 L containers.

Outer Container for Refrigerated Transportation (developmental item)

- A single-use transportation case that can be used for refrigerated and freeze transportation

Options for Use in Safety Cabinets

Stand (available for sizes of 5 L to 20 L)

- A small size rack which can be installed upside down, intended for use in safety cabinets

- The opening faces downward and facilitates complete discharge of residual fluid.

- The container can be handled through the opening of the safety cabinet.

Stand for Filling (available for both 5 L and 10 L)

- Used for filling bags in safety cabinets.

- Holding the opening of the bag with a holder enables stable filling.

- Bags can be used as an alternative to bottles.

Options For Cultures

Culture shaker Device Unit (developmental item)

- To a Culture shaker device, 5 L Steritainer Plus is applicable.

- A detachable tubing unit is attached.

- This unit can also be used in stirring processes in closed systems.

introduction video

Steritainer Plus

Introduction Video

Case Study Video

-

Providing culture medium to a suspension bioreactor (using a Vertical Flip Rack).

-

Conditioning culture medium using a magnetic stirrer.

-

Filling with culture medium in a safety cabinet (using a Stand for Filling).

-

Filling with culture medium in a safety cabinet (using an Outer Container).

-

Providing culture medium to an adherent multi-layer flask (HYPERStack) (using a Stand).

-

Collection of culture solution from an adherent multi-layer flask (HYPERStack) (using an Outer Container).

-

Culture shaker Device (using a 5 L Steritainer Plus)

FAQ

What quality standard tests does Steritainer Plus meet?

What kind of material is Steritainer Plus made from?

What is the advantage of the three-dimensional (3D) shape?

Conventionally, 3D-shape containers have been widely used for retention and transport of fluid. This is because the 3D shape is reasonable in terms of space saving and handling ability.

Steritainer Plus is foldable despite its 3D shape and does not take up much space when it is stored. The 3D bag is also suitable for customers who use bulky bottles or heavy glass bottles.

What is the reason for the 5, 10, and 20 L product specifications?

For the currently available 3 types, fully automated production and online automated leak testing have been established. We decided to minimize manual processes as much as possible to ensure the quality of the products.

The products with these volumes have to be handled manually, and the heavy weight becomes overloaded. The optional vertical flip rack can lighten the load on persons who handle the bags. We developed the product with the aim of standardizing the work so it can be done safely by anyone.

What is the difference between Steritainer Plus and Steritainer?

The difference is in the packaging units. Steritainer Plus is individually packaged. By contrast, collective packaging (bulk) is used for Steritainer with one package containing 25 pieces of the 20 L bags and 50 pieces of the 10 L and 5 L bags.

What kind of tests have been conducted?

What is difference between the “3-port connector” and “3-port connector ASSY” in use?

We can also offer various standard options specialized to your intended use. These options can be selected in combinations depending on the purpose, and you can customize the options along with freely-designed tube patterns.