What are clean containers?

Clean containers are containers that are produced in a strictly particle-controlled environment using carefully selected low-elution-grade material.

They are used to safely transport and store liquids that require strict quality control, such as high-purity chemicals used to manufacture semiconductors, pharmaceuticals, cosmetics, and fragrances. Depending on their size, they are also called clean bottles, clean polycons, and clean drums.

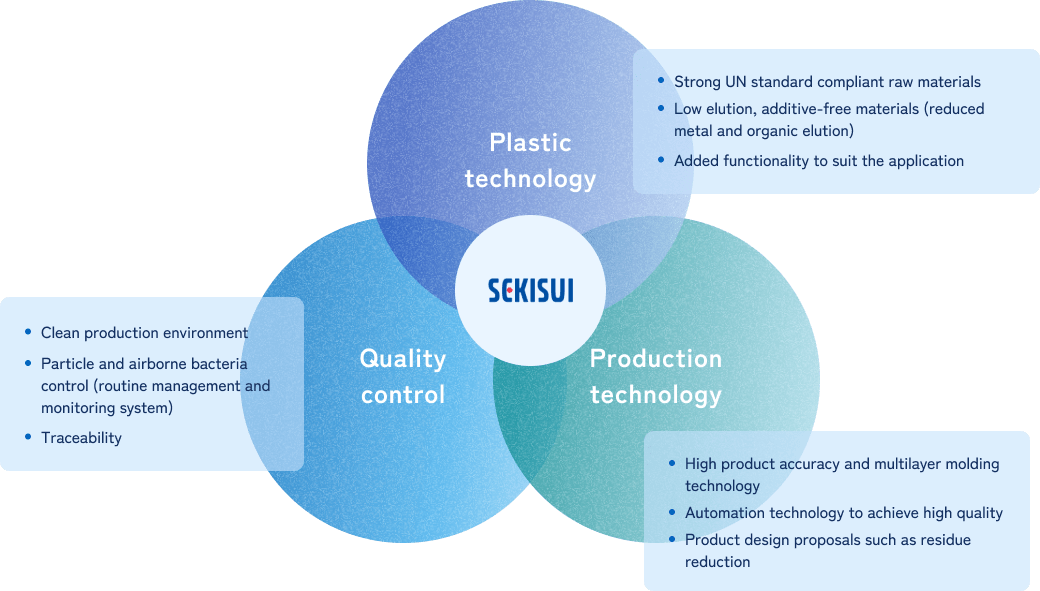

introduction SEKISUI SEIKEI’s clean container solutions

Control of the cleanliness inside the container

(particle control)

-

10-20L Polycon

≥0.3μm 30 or fewer/ml

-

200L Polydrum

≥0.5μm 10 or fewer/ml

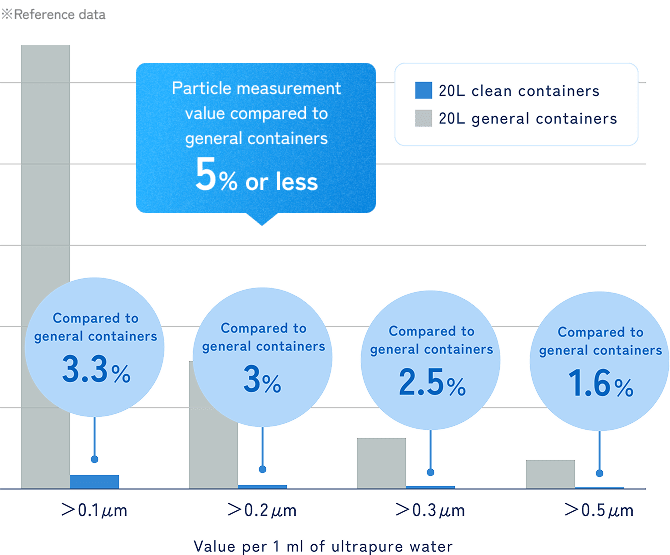

Clean containers vs. general containers (internal comparison)

Particle measurement value

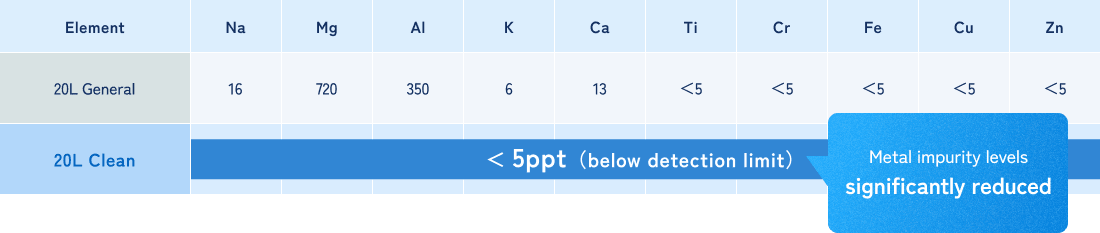

Metal impurities value

Measured by ICP-MS after filling 20L of ultrapure water and storing it for 1 day (24h) at 40°C

Detection limit: 5ppt; unit: ppt

Achieve high quality with particle control and low elution material

products Lineup of clean container products

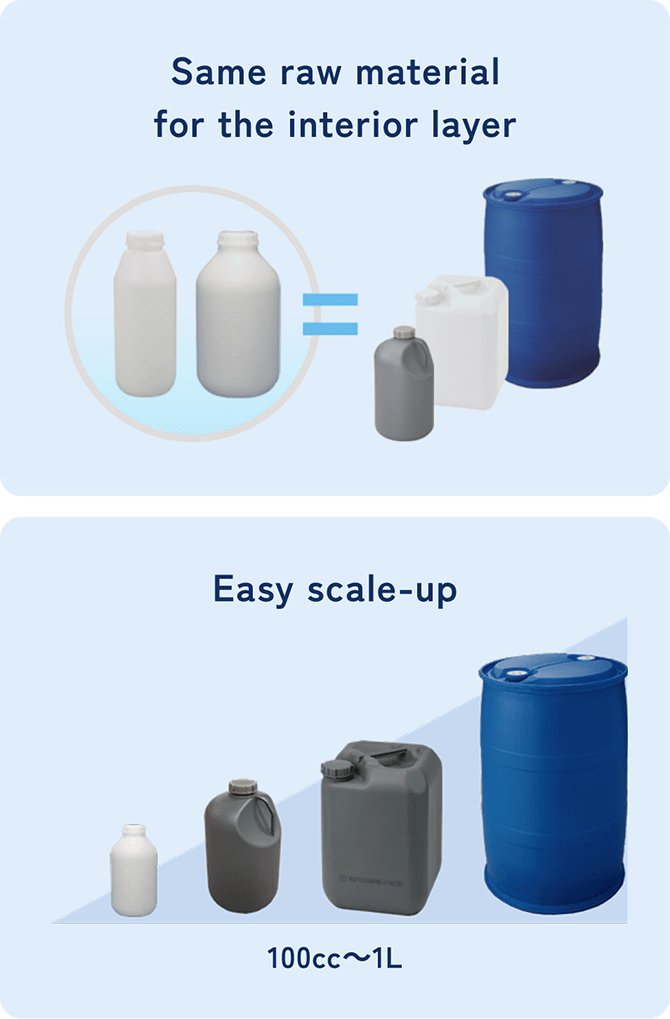

We offer clean containers with a high level of cleanliness in a wide range of sizes, such as 100cc-1L bottles, 10L-20L clean polycons, and 200L drums.

| Capacity | 100cc | 250cc | 500cc | 1L | 10L | 13L | |

|---|---|---|---|---|---|---|---|

| Shape |  |

|

|

|

|

|

|

| Capacity | 01AL-F | 02AL-F | 05AL-F | 1AL-F | 10AL | 10UN | 13SL |

| Color | |||||||

| Capacity | 20L | 200L | ||||

|---|---|---|---|---|---|---|

| Shape |  |

|

|

|

|

|

| Capacity | 20BL2 | 20SL5 | 22AH | SPD200-2 | ||

| Color | ||||||

features Features of clean containers

- It is easy to scale up from laboratories to mass production.

- Since the same grade of raw material is used in every size (grade is added), it is not necessary to evaluate the performance of the container at the time of scale-up.

- Superior Clean Performance to Maintain Content Fluid Quality

- To limit the elution of components into the contents as much as possible.

- Complies with UN standards required for transporting hazardous materials

- All volumes comply with UN standards (UN Recommendations on the Transport of Dangerous Goods)

For Sekisui clean containers, we cover every step from

research and development and sampling to mass production

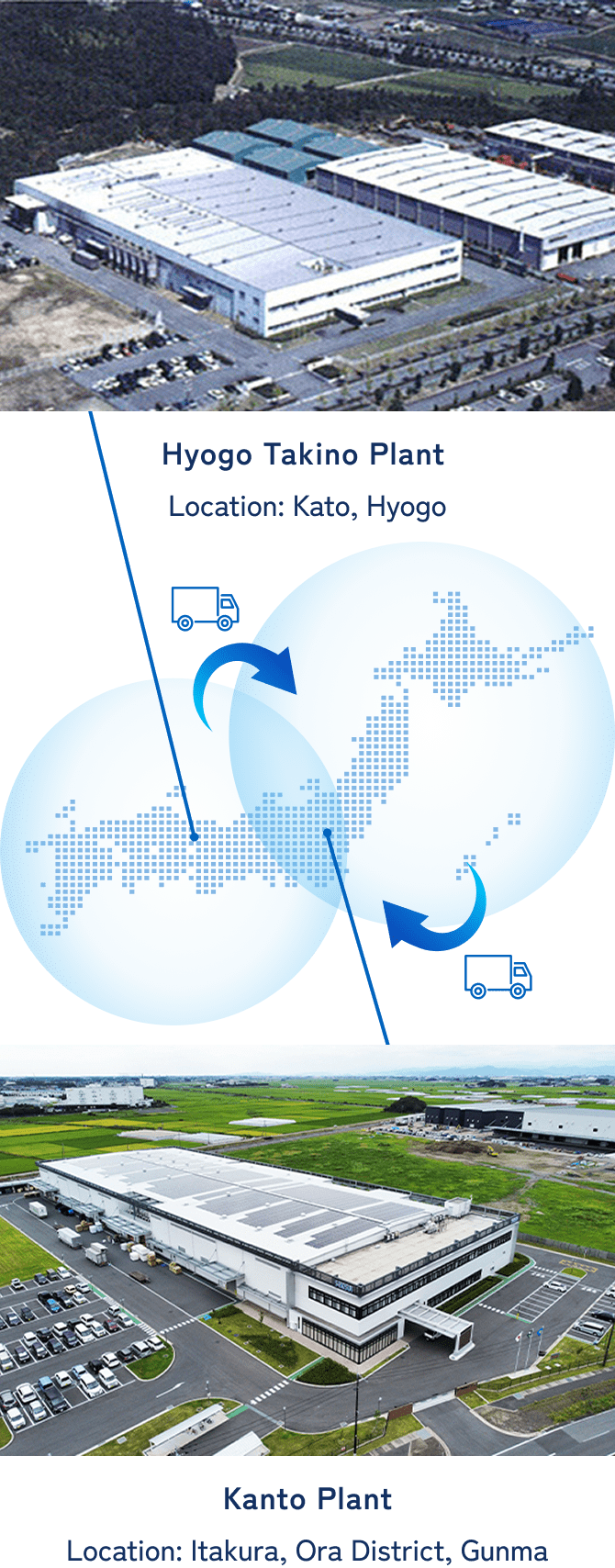

Stable supply with the use of multiple production sites

features Other features of clean containers

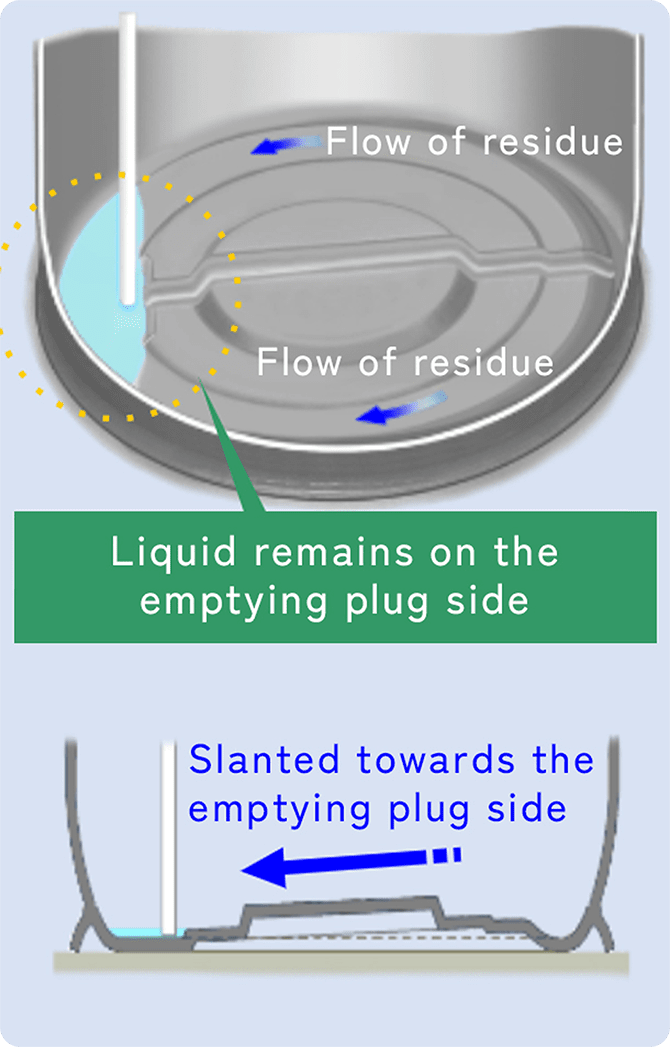

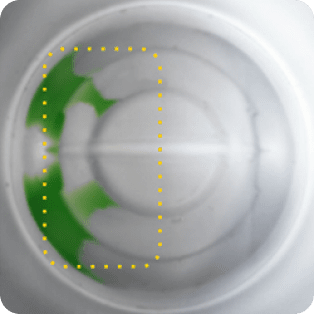

Low residue type

Efficiently discharges the contents leaving as little residue as possible.

-

-

Structure

Base shape that enables efficient discharge of contents

-

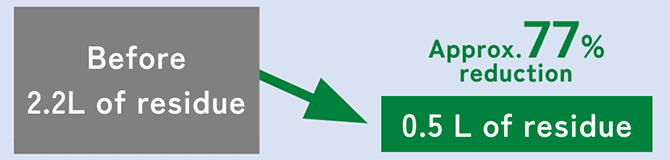

Comparison of amount of residue

Checking method: Use a connector and a pump to suck out water until it stops and measure the amount of liquid that remains

-

Regular product

-

Residue-reduction product

Problem: Residual liquid accumulates diagonally from the liquid emptying plug and cannot be sucked out.

-

Leads to efficient use of liquid chemicals and reduction in wasted residual liquid